Products

Product List

Cracking furnace device

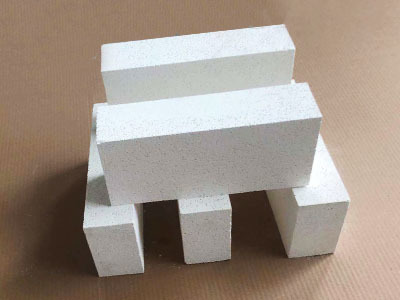

Products required for the cracking furnace installation: high-strength mullite brick series products and supporting clay, high-strength and low-conductivity castable series products.

Classification:

Keywords: high-strength wear-resistant materials wear-resistant corrosion-resistant materials

Description

Products required for the cracking furnace installation: high-strength mullite brick series products and supporting clay, high-strength and low-conductivity castable series products.

Lining materials for catalytic cracking units

| Category | Level | Hot surface temperature ℃ | Bulk density Kg/m3 | Compressive strength MPa | Bending strength MPa | Line change rate % | Thermal conductivity w/m.k | Al2O3 % | Fe2O3 % | Normal temperature wear resistance cm3 |

| High wear resistance | Grade A (AA) | 110 | ≤3100 | ≥80 | ≥10 | _ | _ | ≥90 | ≤1.0 | ≤6 |

| 540 | ≤2950 | ≥80 | ≥10 | _ | _ | |||||

| 815 | ≤2950 | ≥80 | ≥10 | 0~-0.25 | ≤1.5 | |||||

| Wear-resistant | B1 level (B01) | 110 | ≤2500 | ≥60 | ≥8 | _ | _ | ≥50 | ≤2.5 | ≤10 |

| 540 | ≤2450 | ≥50 | ≥7 | _ | _ | |||||

| 815 | ≤2450 | ≥50 | ≥7 | 0~-0.2 | ≤0.9 | |||||

| B2 level | 110 | ≤2300 | ≥40 | ≥6 | _ | _ | ||||

| 540 | ≤2250 | ≥30 | ≥5 | _ | _ | |||||

| 815 | ≤2250 | ≥30 | ≥5 | 0~-0.2 | ≤0.8 | |||||

| Thermal insulation and wear resistance | LC1 | 110 | ≤2000 | ≥50 | ≥7 | _ | _ | ≥40 | ≤1.0 | ≤10 |

| 540 | ≤1950 | ≥40 | ≥6 | _ | 0.45~0.55 | |||||

| 815 | ≤1950 | ≥40 | ≥5 | 0~-0.1 | 0.5~0.59 | |||||

| C1 level | 110 | ≤1800 | ≥40 | ≥7 | _ | _ | ≥40 | ≤1.0 | ≤18 | |

| 540 | ≤1750 | ≥35 | ≥6 | _ | 0.45~0.55 | |||||

| 815 | ≤1750 | ≥35 | ≥5 | 0~-0.2 | 0.5~0.59 | |||||

| C2 level (C03) | 110 | ≤1600 | ≥35 | ≥5 | _ | _ | ≥36 | ≤2.0 | ≤20 | |

| 540 | ≤1550 | ≥30 | ≥4 | _ | 0.35~0.42 | |||||

| 815 | ≤1550 | ≥25 | ≥3 | 0~-0.2 | 0.4~0.49 | |||||

| C3 level (LC4) | 110 | ≤1400 | ≥20 | ≥3 | _ | _ | ≥36 | ≤2.0 | ≤15 | |

| 540 | ≤1350 | ≥15 | ≥2.5 | _ | 0.26~0.35 | |||||

| 815 | ≤1350 | ≥15 | ≥2.5 | 0~-0.2 | 0.34~0.4 | |||||

| Thermal insulation | D02 | 110 | ≤1400 | ≥20 | ≥4.5 | _ | _ | |||

| 540 | ≤1350 | ≥15 | ≥3.5 | 0~-0.2 | _ | |||||

| 815 | ≤1350 | ≥14 | ≥3 | _ | 0.32~0.4 | |||||

| D1 level | 110 | ≤1100 | ≥8 | ≥2.5 | _ | _ | ||||

| 540 | ≤1050 | ≥7 | ≥2 | _ | ≤0.25 | |||||

| 815 | ≤1050 | ≥7 | ≥1.5 | 0~-0.2 | ≤0.28 | |||||

| D2 level | 110 | ≤1000 | ≥7 | ≥2 | _ | _ | ||||

| 540 | ≤950 | ≥6 | ≥1.5 | _ | ≤0.23 | |||||

| 815 | ≤950 | ≥6 | ≥1.5 | 0~-0.2 | ≤0.25 | |||||

| 1. The thermal conductivity is tested according to the flat plate method. 2. Performance indicators are measured values without adding steel fibers. 3. The data of the 815℃ reburning line change rate and the 815℃ line change rate should be the same. 4. Thermal shock stability (815℃, air cooling) Class A, Class C: ≥10 times. 5. The thermal conductivity of Class A high wear-resistant lining is not used as a material testing and evaluation index, and is only used as a reference for calculating wall temperature. | ||||||||||

Related Products

Message