Products

Product List

Sulfur recovery unit

Products required for sulfur recovery equipment: chrome corundum bricks, corundum mullite bricks, lightweight mullite brick series products and supporting clay, corundum castables, acid-resistant castables, and heat-insulating ceramic pipe series products.

Classification:

Keywords: high-strength wear-resistant materials wear-resistant corrosion-resistant materials

Description

Products required for sulfur recovery equipment: chrome corundum bricks, corundum mullite bricks, lightweight mullite brick series products and supporting clay, corundum castables, acid-resistant castables, and heat-insulating ceramic pipe series products.

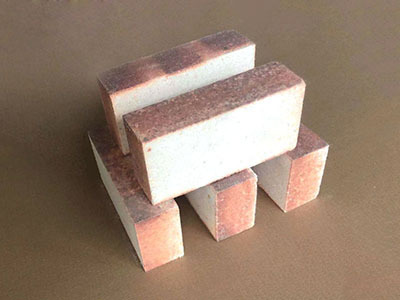

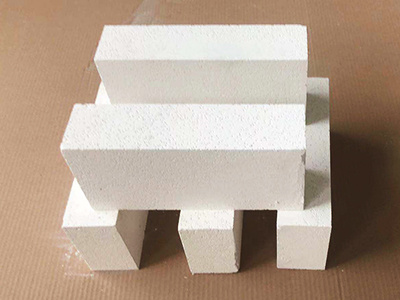

Refractory materials for sulfur recovery equipment (1)

Technical indicators of series of refractory materials

| Performance Name | Maximum operating temperature ℃ | Volume Density Kg/m3 | Compressive strength MPa | Bending strength MPa | Line change rate % | Thermal conductivity coefficient w/m.k | Chemical composition% | |||||

| 110℃ | 110℃ | 1100℃ | 1400℃ | 110℃ | 1100℃ | 1400℃ | 1400℃ | 350℃ | Al2O3 | Fe2O3 | ||

| GCL-3000 corundum castable | 1750 | ≤3000 | ≥50 | ≥80 | ≥100 | ≥6 | ≥8 | ≥10 | 0~-0.6 | ≥90 | ≤0.7 | |

| QMS-1200 | 1400 | ≤1250 | ≥8 | ≥6 | ≥2.0 | ≥2.0 | ±0.35 (1100℃) | ≤0.3 | ||||

| GMS-3000 corundum mullite castable | 1500 | ≤2900 | ≥60 | ≥90 | ≥100 | ≥7 | ≥10 | ≥10 | ±0.45 | ≥75 | ≤1 | |

| Anchor Brick | 1750 | ≤2950 | ≥50 (normal temperature and pressure resistance) | 0~-0.6 | ≥90 | ≤0.7 | ||||||

| Acid-resistant lining | 1200 | ≤1250 | ≥8 | ≥6 | ≥2.0 | ≥2.0 | Acid resistance ≥92 | ≤0.35 | ≤35 | ≤1 | ||

| Reactor lining | 1400 | ≥1200 | ≥16 | ≥20 | ≥3.0 | ≥3.5 | 0~-0.2 (815℃) | Acid resistance ≥70 | ≤3 | |||

| Condenser lining | 1300 | ≥1200 | ≥12 | ≥16 | ≥2.5 | ≥3.0 | 0~-0.2 (815℃) | Acid resistance ≥70 | ≤3 | |||

| Acid-resistant ceramic tiles | 600 | ≤2000 | ≤35 | |||||||||

| Furan cement | 300 | ≥7(tensile strength) | ≥2(bonding strength) | (referring to hard time) no later than 12 hours | ||||||||

| Acid-resistant cement | ≥300 | |||||||||||

Refractory materials for sulfur recovery equipment (1)

Technical indicators of series of refractory materials

| Name Indicator | High purity low silicon corundum brick | Pure corundum brick | Mullite combined with corundum bricks | Chrome Corundum Brick | Composite brown corundum brick | |

| Chemical composition (%) | Al2O3 | ≥99.5 | ≥98.5 | 90 | ≥88 | ≥78 |

| SiO2 | ≤0.1 | ≤0.5 | 8 | ≥14 | ||

| Fe2O3 | ≤0.1 | ≤0.1 | 0.8 | ≤0.3 | ||

| Cr2O3 | 10~12 | |||||

| Bulk density (g/cm3) | ≥3.15 | ≥3.0 | 2.8~3.0 | ≥3.15 | ≥3.0 | |

| Normal temperature compressive strength (Mpa) | ≥100 | ≥80 | 70~110 | 80~100 | 98 | |

| High temperature flexural strength (Mpa) | ≥9.8 | |||||

| 0.2Mpa load softening temperature T0.6 (℃) | ≥1700 | ≥1680 | 1650 | ≥1700 | ≥1680 | |

| Refractory degree (℃) | ≥1900 | ≥1850 | 1790 | |||

| Thermal shock stability 1100℃~water cooling (times) | ≥6 | ≥6 | 8 | |||

| Reheat line change 1600℃×3h(%) | ≤0.1 | ≤0.1 | ±0.5 | 0~0.2 | 1500℃ 0~0.2 | |

| Apparent porosity (%) | ≤17 | ≤18 | 18~21 | ≤18 | ≤18 | |

Related Products

Message